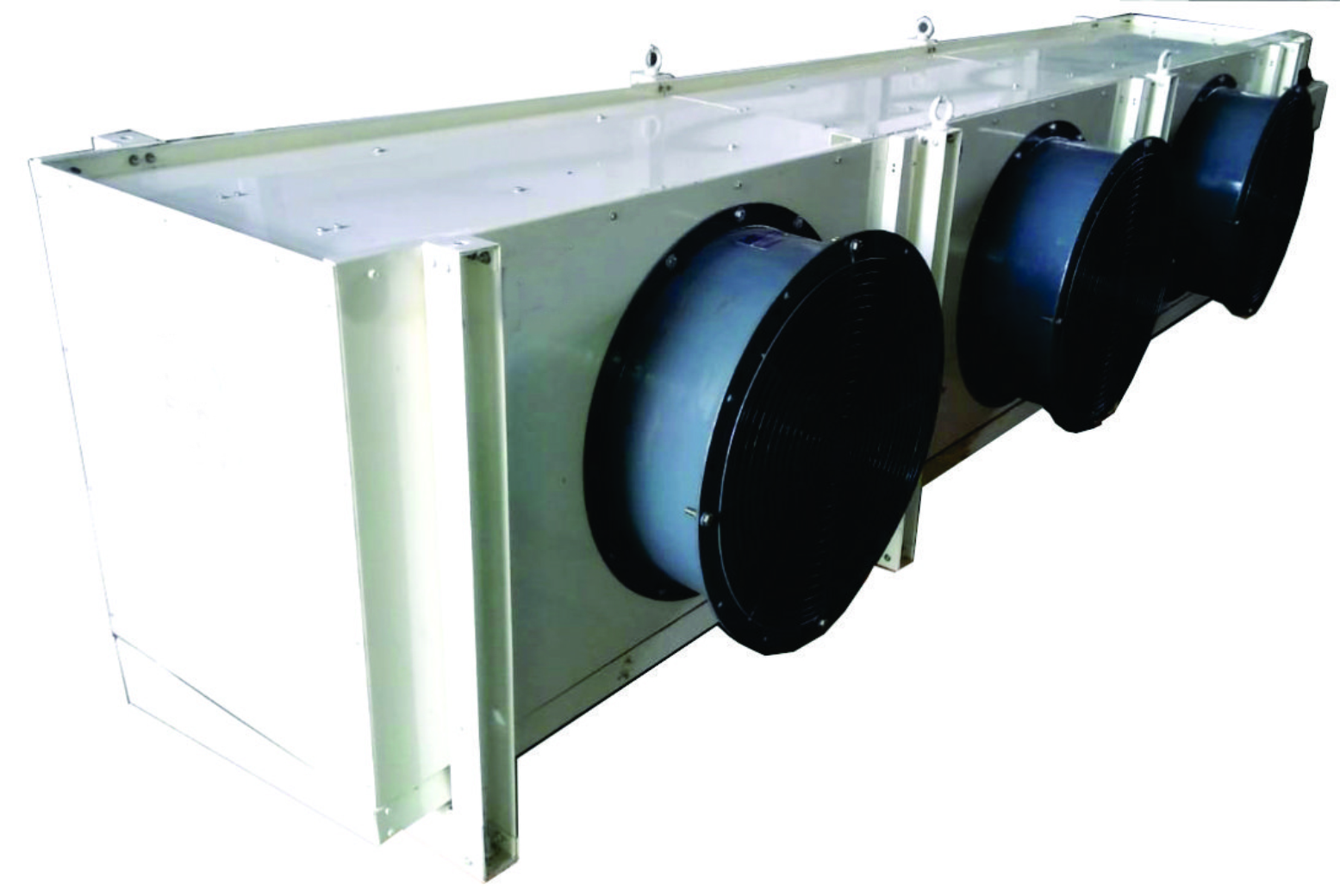

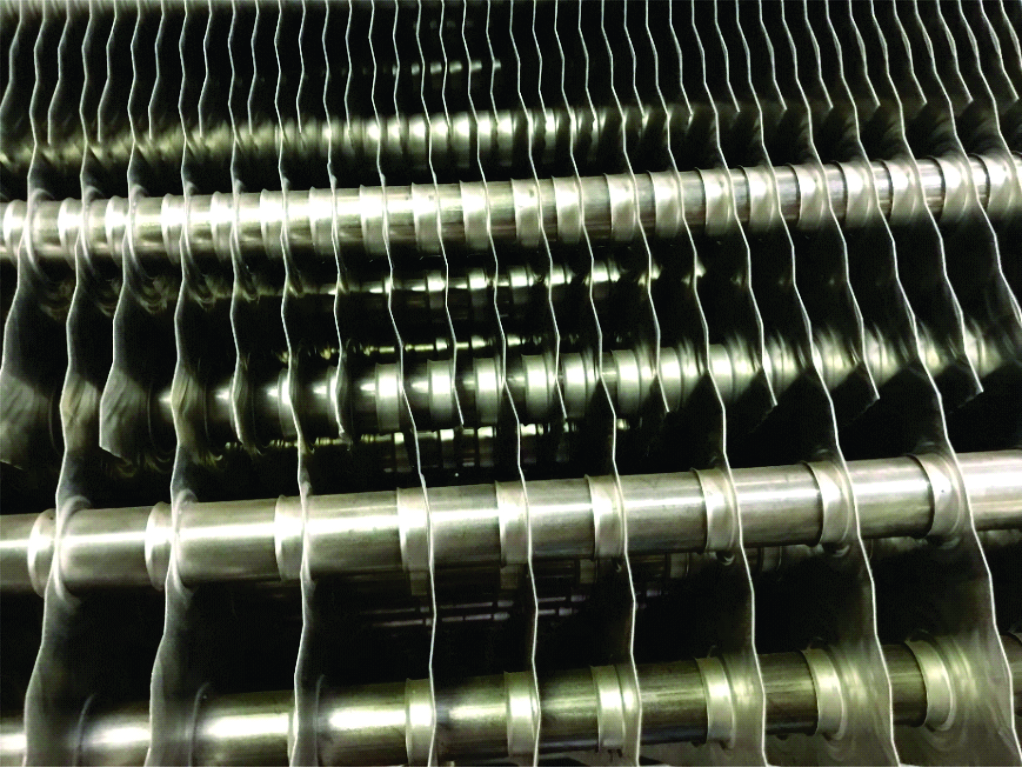

fil coils energy saving air-cooling units are available in various capacities ranging from4000 CFM to 50000 CFM. Coil capacity is based on sensible heat removal, medium frosted coil condition. Temperature difference is the temperature of the air entering the coil and the coil evaporating temperature.

These coils are For cold stores, processing halls, distribution and storage areas, blast freezers normal and deep freezing areas, IQF and CA stores.

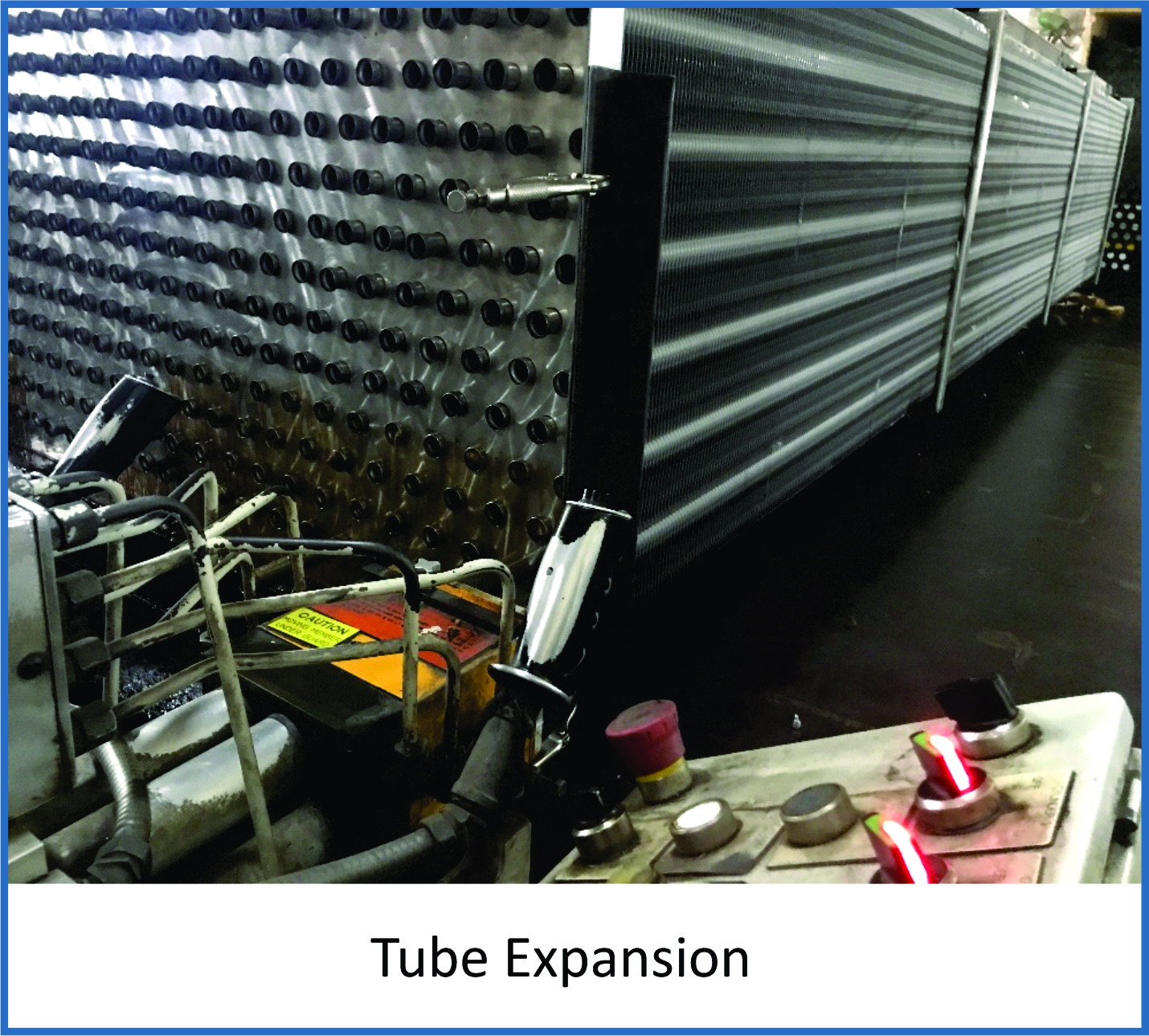

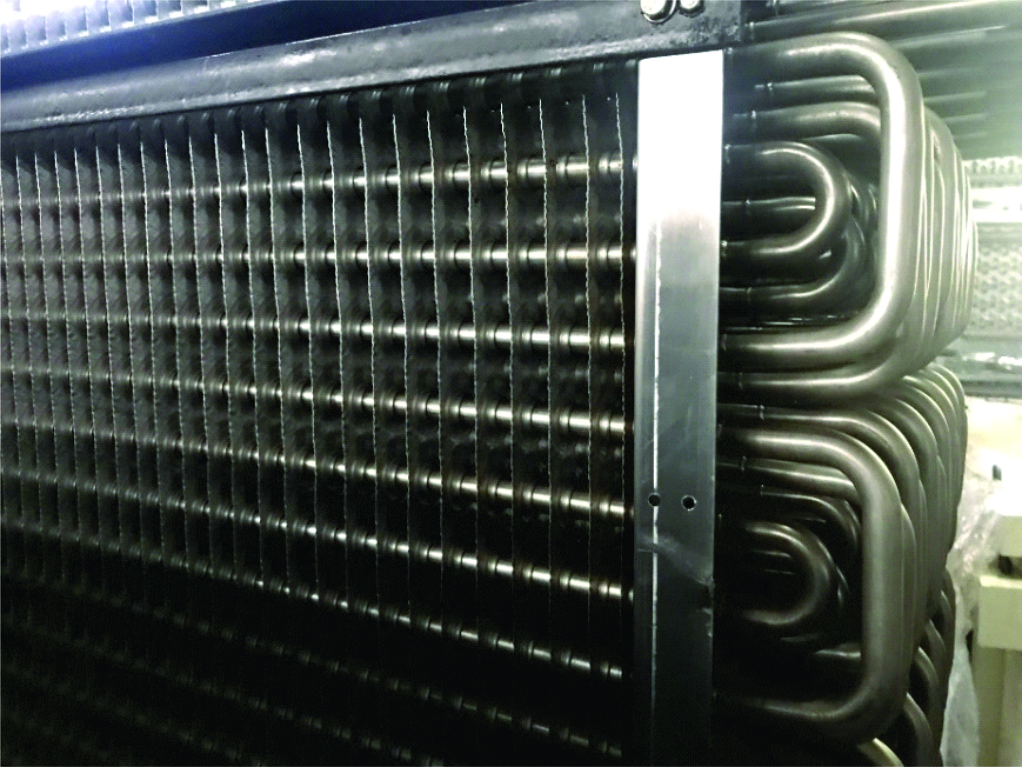

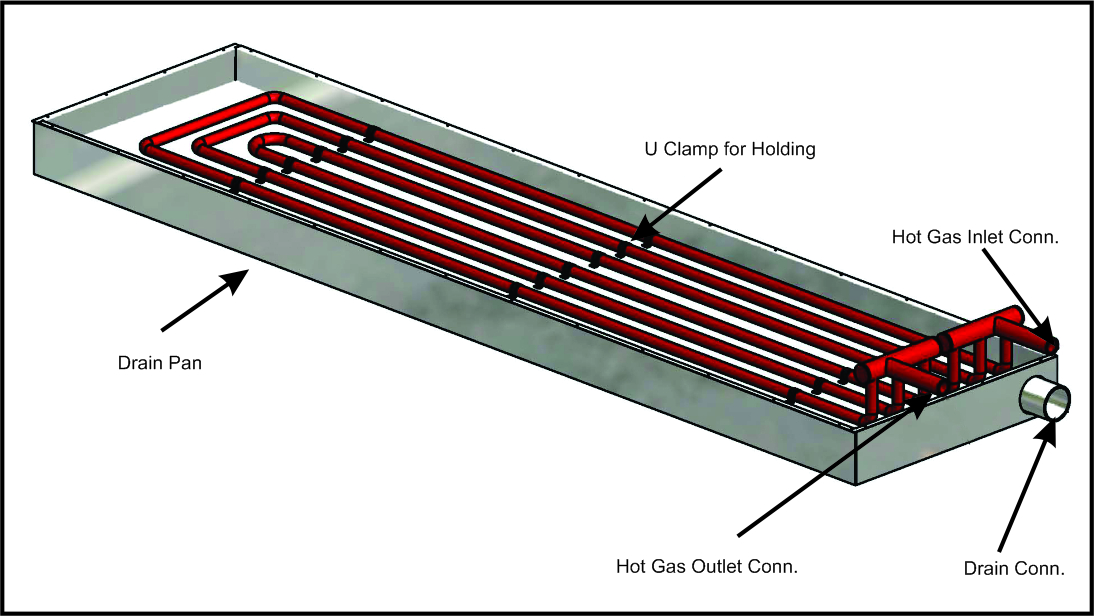

Thermal Insulated Drain pan is placed between the inner drain pan and outer cover. Both the inner drain pan and outer cover are fabricated from galvanized sheet. Multi circuit Coils are provided on entire drain-pan surface to provide effective defrosting within shortest period.

Easy opening functions for fans creates an easy access for cleaning inside of the units

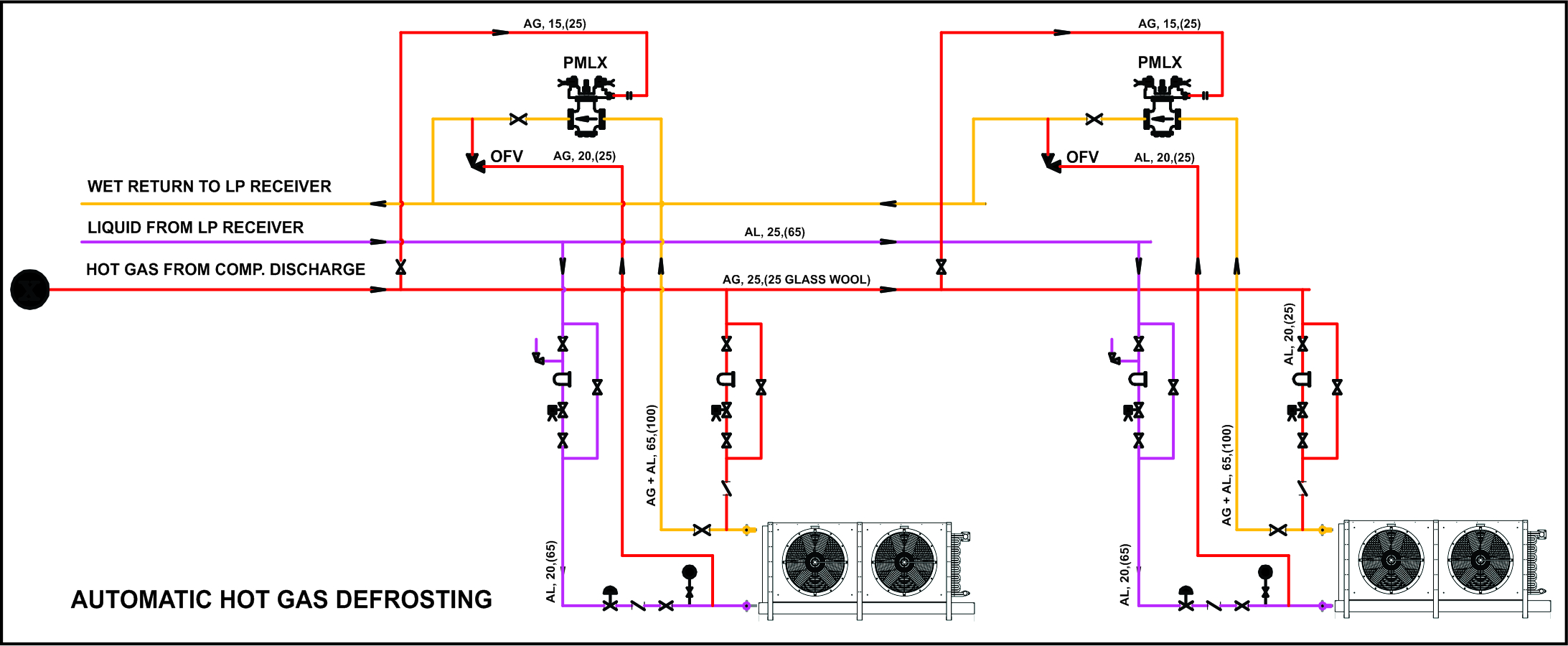

HOT GAS DEFROST : A multi-circulated pan coil is welded to the inner pan. The coil design reduces pressure drop, increases hot gas flow and shortens overall defrost times.

WATER DEFROST : A Spray tray with full coverage non-clogging perforations and an oversized drain pan connection are provided. Spray tray and perforations are easily accessible.